Table of Contents

Table of Contents

Understanding Engine Power Measurement

It is important that one understands that there is no written rule to measure power directly. It has a lot of dynamometers which can measure the torque and allow the power to be calculated. This is a basic equation which allows one to develop design and development work. There are two main methods to find the right power which is used in the automotive industry.

Dynamometer Testing Methods

The automotive industry relies heavily on precise measurement techniques to evaluate engine performance. Dynamometers serve as the primary instruments for these assessments, providing accurate torque readings that form the foundation for power calculations.

Power Calculation Fundamentals

The relationship between torque and power follows established mathematical principles that engineers use throughout the design and development process. Understanding these calculations is crucial for optimizing engine performance and meeting industry standards.

Car Engines

There are two small valves like the cast-iron block and head, pushrod valve train. It is hardly a state of the art which is a multivalve aluminium engine which has 50% more power and can weigh two times as much. There is plenty of cash flows which will allow you to have a very reliable service. The crossflow allows you to get some kind of modification. This allows one to have some of the best ad smooth flow. This over a period of time can allow you to get the right speed for the operation on rolling roads.

Engine Block Construction

Modern engine blocks represent a significant evolution from traditional cast-iron designs. The materials and manufacturing processes used in contemporary engines directly impact their performance characteristics, durability, and overall efficiency.

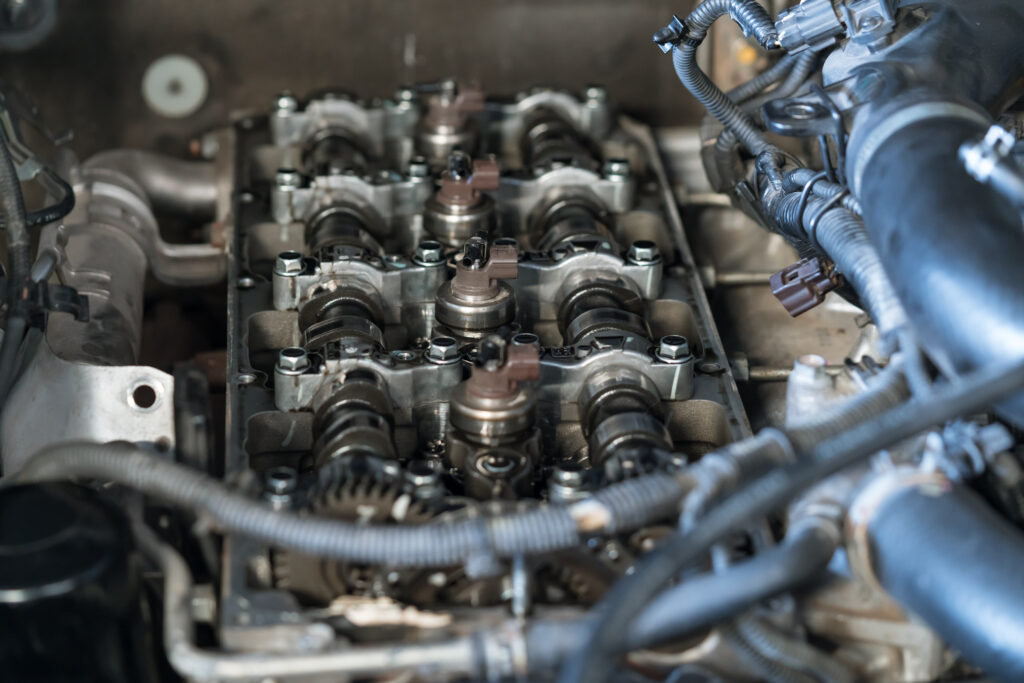

Valve Train Systems

The valve train system plays a critical role in engine breathing and performance. Different configurations offer varying advantages in terms of power output, reliability, and maintenance requirements.

Crossflow Engine Design

The crossflow was the successor to the pre crossflow and was simply a modular engine. This allows them to stay the same, allowing you to have the right capacity and can get progressively better with longer strokes and cranks. They also have a small engine which is oversized like a bike engine. You can exactly have the same big valve which will allow you to build the real screamer.

Modular Engine Architecture

The modular approach to engine design provides significant advantages in manufacturing flexibility and performance optimization. This system allows for various configurations while maintaining core structural elements.

Stroke and Crank Modifications

Engine capacity can be enhanced through careful modifications to stroke length and crankshaft specifications. These changes require precise engineering to maintain reliability while achieving performance gains.

Engine Displacement and Capacity

The crossflow can easily be bored out to ensure that there is a long way to go when it comes to gaining capacity. There is an 83.5 mm which gives 77.6 mm stroke crank although it might seem like it is pushing limits. It is still oversized from the features that it comes in. There is pressure testing which can be blocked. The capacity does very less to give it the right peak of power and can allow you to have the right torque that can increase the rpm and cab generate drops in the right proportion.

Bore and Stroke Relationships

The relationship between bore diameter and stroke length significantly affects engine characteristics. Optimizing these dimensions requires careful consideration of power delivery, torque curves, and operational requirements.

Piston Specifications

The standard piston can be oversized up to 0.090, which can give 83.25mm. This is supplied in an unfinished flat which can be expensive for most.

Pressure Testing Considerations

Proper pressure testing ensures engine integrity and performance reliability. Blocked passages or inadequate testing can lead to performance issues and potential engine damage.

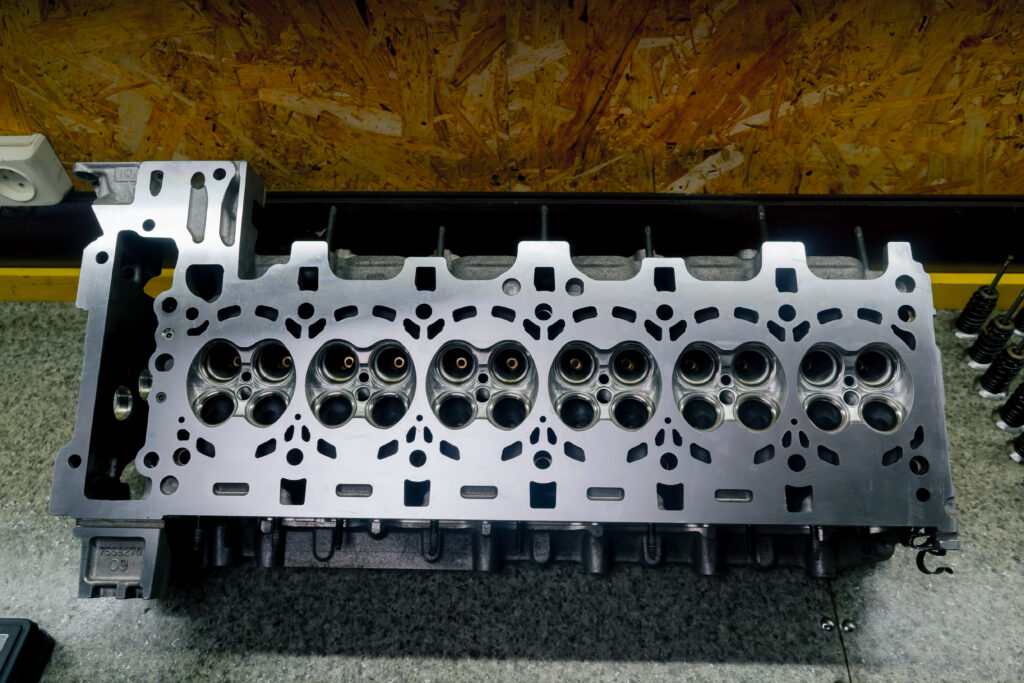

Cylinder Head

This is a port design which is actually pretty good and very straight to the point. It has a very reasonable downdraft and can have a flow per square inch of value can be pretty high. The engine size of the valves is quite smaller. Most engines have bigger valves, and one of the first is the 41.3 mm inlet valve which is available off-shelf which can be found for a lower price. The engine might have its very own problem, but with a bit of variation, one can easily find the right tool allowing the right drill.

Port Design and Flow Characteristics

Cylinder head port design directly influences engine breathing efficiency and overall performance. The geometry and finish of these passages determine how effectively the engine can move air and fuel mixtures.

Downdraft Configuration Benefits

The downdraft design offers specific advantages in terms of flow characteristics and installation requirements. This configuration can provide improved volumetric efficiency when properly implemented.

Flow Rate Optimization

Achieving high flow rates per square inch of port area requires careful attention to port shape, surface finish, and transition areas. These factors collectively determine the cylinder head’s effectiveness.

Valve Sizing and Selection

Valve dimensions play a crucial role in engine breathing capacity and performance potential. The balance between valve size and port design determines optimal flow characteristics.

Inlet Valve Specifications

The 41.3 mm inlet valve represents a common specification that provides good availability and cost-effectiveness. This size offers a practical balance between performance and affordability.

Valve Availability and Cost Considerations

Off-shelf valve options provide cost-effective solutions for many applications. However, custom specifications may be necessary for specialized performance requirements.

Cylinder Head Modifications

Engine modifications require careful planning and execution to achieve desired results while maintaining reliability. The availability of appropriate tools and components affects the feasibility of various modification approaches.

Drilling and Machining Requirements

Proper tooling and techniques are essential for successful cylinder head modifications. The right equipment ensures precision and maintains the integrity of the component.

Problem-Solving Approaches

Each engine configuration may present unique challenges that require specific solutions. Variations in approach often lead to successful outcomes when standard methods prove insufficient.